vickers hardness test meaning|vickers hardness chart : commercial What Does Vickers Hardness Test Mean? The Vickers hardness test is a test performed to measure the hardness of materials, specifically thin sections and small parts. It . Resultado da Cresci e Perdi Mega Store Sorocaba, São Paulo, comentários de clientes, mapa de localização, números de telefone, horário de trabalho .

{plog:ftitle_list}

webVídeos Pornôs Com Morena Cavalona. Mostrar 1-32 de 46353. Quer dizer morena cavala ? 13:48. Huge Boobs Tifa GORGEOUS Brunette Stripper Step Sister Fucks Step Brother .

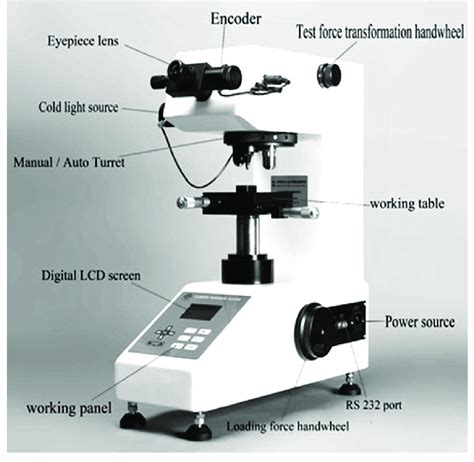

What is the Vickers Hardness Test. NextGen explains the machine, its applications and the necessary consumables required for the Vickers Hardness Testing needs.The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of .

The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 .Find an explanation of how to read a Vickers hardness value (e.g. “640 HV30”), and of the meaning of the numbers and letters. What Does Vickers Hardness Test Mean? The Vickers hardness test is a test performed to measure the hardness of materials, specifically thin sections and small parts. It .

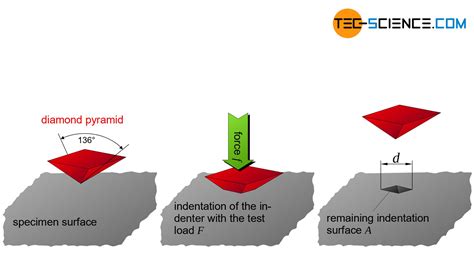

The Vickers hardness test is a versatile hardness test method, used for both macro and micro hardness testing. It has a broad load range, and is suitable for a wide range of applications and materials.Vickers Hardness Testing Formulas, Calculator and Review. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. The unit of hardness given by the test is known as the Vickers Pyramid .The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. .

The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the micro to the low . The Vickers hardness test can be applied for micro-testing. Knoop: Specifically used to test thin or brittle materials, as it gives a meaningful reading with a shallow indentation. It uses an elongated pyramid to make the .The definition of hardness testing is ‘a test to determine the resistance a material exhibits to permanent deformation by penetration of another harder material.’ . For the Vickers hardness test, the measured diagonals should not deviate more than 5.0% from each other. For the Knoop hardness test, the two halves of the long diagonals must .

Vickers Hardness Test. The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness .

vickers hardness testing machine diagram

The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. . HV = Vickers hardness When the mean diagonal of the indentation has been determined the Vickers hardness . For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the Vickers hardness values are comparable to a certain degree with the Brinell hardness values (applies to approx. 400 HBW or 400 HV). The .Vickers hardness, a measure of the hardness of a material, calculated from the size of an impression produced under load by a pyramid-shaped diamond indenter. Devised in the 1920s by engineers at Vickers, Ltd., in the United Kingdom, the diamond pyramid hardness test, as it also became known, Rockwell hardness definition: 0.002mm residual indentation depth is a Rockwell hardness unit. K – constant, 130 for steel ball indenter and 100 for diamond indenter . The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers Hardness (1) The .

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Since the .According to ISO 6507: The dwell time of the test load, but only if this is not between 10 and 15 seconds (uncommon in practice) Examples. 640 HV30. 640 .hardness value; HV .as per Vickers; 30 .with test load of 30 kgf (or test force of 294.2 N ) 610 HV10/30. 610 .hardness value; HV .as per Vickers; 10 .with test load of 10 kgf (or .

This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and Vickers hardness test.. The Vickers hardness scale, named after the company where it was developed in 1921, is the focus of this article.

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method , which is mostly used for small parts, thin sections, or case depth work.In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below). After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the sample is measured using a microscope.3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.The Vickers hardness test uses a square-based pyramid diamond indenter with an angle of 136° between the . 10 s to 15 s. After the force has been removed, the diagonal lengths of the indentation are measured and the arithmetic mean, d, is calculated. The Vickers hardness number, HV, is given by: HV = Constant × Test force / Surface area of .

The meaning of VICKERS HARDNESS TEST is an indentation hardness test for metals in which a 136-degree diamond pyramid is pressed into the surface of the metal being tested by a load of 5 to 120 kilograms.The Vickers hardness tester series "Qness" takes Vickers hardness testing to a whole new level. Our high-end models of the latest generation combine short cycle times with maximum precision. . Vickers hardness test results . According to DIN EN ISO 6507-1, the result of a Vickers test is given as follows: 700 HV 10 / 20 ⇒ Hardness value as .d = mean diagonal of impression, mm, and a = face angle of diamond = 136°. 3.4 Vickers hardness test—an indentation hardness test using calibrated machines to force a square-based pyramidal diamond indenter having specified face angles, under a prede-termined force, into the surface of the material under test andThe Vickers method has the following advantages: The Vickers method can be used with any and all materials and test specimens, from soft to hard, as the procedure covers the entire hardness range.

I. Significance of Vickers Hardness Standard Test. Vickers hardness test is the nondestructive testing method, which is significant while evaluating materials, a quality check of the manufacturing procedure, and creating new products. Vickers hardness testing method is the only procedure that we can say is universal because of its scaling, as it can be used for testing .Vickers and Knoop hardness values are not designated by a number alone because it is necessary to indicate which force has been employed in making the test. The hardness numbers shall be followed by the symbol HV for Vickers hardness, or HK for Knoop hardness, and be supplemented by a value representing the test force in kgf. Examples: 450 HV .

The specimen size (the minimum clearances between test points (indent spacing) and from the specimen edge (edge clearance) for Vickers defined in the standard must be observed); The specimen thickness (the specimen thickness must be at least 1.5 times the indentation diagonals, i.e. the minimum specimen thickness must be between 0.085 and 6.5 mm); The surface .What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a mineral is defined as its "resistance to being scratched". A list of the Mohs Hardness Scale Minerals is shown in the table below.The tests can generally be applied to the finished product without significant damage. Commercial popularity of the Rockwell hardness test arises from its speed, reliability, robustness, resolution and small area of indentation. See also: Brinell Hardness Test. See also: Vickers Hardness Test. See also: Knoop Hardness TestIn-depth definition of hardness testing involves evaluating the hardness level of a material by measuring the depth or area of indentation left by an indenter of a specific shape, applied with a specific force for a specific time. . The three primary methods of testing hardness in engineering are the Brinell hardness test, the Vickers .

3. Vickers Hardness (HV) Vickers hardness is determined by pressing a diamond square cone with a 136° top angle and a load of up to 120kg into the material’s surface. The Vickers hardness value (HV) is calculated by dividing the load by the surface area of the indentation pit, expressed in kgf/mm². 4. Leeb Hardness (HLD)Definition. The Vickers hardness test is a method used to measure the hardness of materials, specifically metals, by indenting the material with a diamond pyramid under a specific load. This test provides a hardness value that correlates with the material's resistance to deformation and wear, linking it to surface hardness and elasticity, which .

The equation based definition of hardness is the pressure applied over the contact area between the indenter and the material being tested. As a result hardness values are typically reported in units of pressure, although this is only a "true" pressure if the indenter and surface interface is perfectly flat. . Vickers hardness test (HV .

vickers hardness test theory

WEB12 de abr. de 2023 · A mensagem intrínseca da reportagem é a de que a esposa de um ministro foi indevidamente beneficiada com um alto cargo num ministério. Para esconder a benesse, evitou-se a publicação em Diário da República (DR). Se foi cometida alguma irregularidade com a falta de publicação em DR do seu cargo no Ministério das .

vickers hardness test meaning|vickers hardness chart